From Seed to Sale: How RFID Is Streamlining the Cannabis Industry (Part One)

November 1, 2022

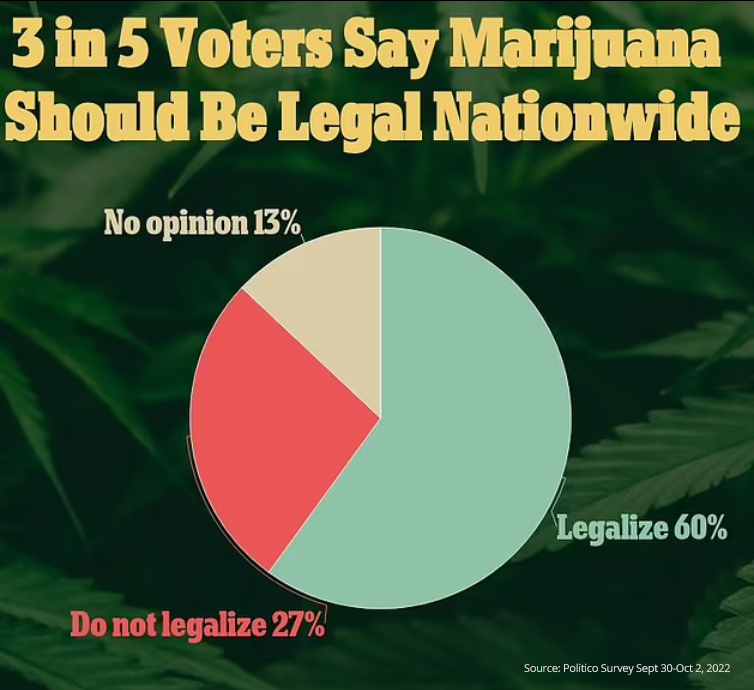

According to the DailyMail, voters in five states, namely Arkansas, Maryland, Missouri, North Dakota, and South Dakota, will decide in the U.S. in November 2022 whether to legalize cannabis for people aged at least 21 years old. Although several efforts to end the federal ban on marijuana have failed, recent polling shows that nearly 60% of voters want it legalized nationwide. It looks like cannabis is all set to become legal for millions of Americans within the next few months.

With cannabis likely to become more widely available to consumers, there is one big challenge for companies: how to ensure safe and smart operations and packaging. Cannabis brand protection is a big concern for growers. Just like several other consumer brands, cannabis has become susceptible to counterfeits, diversion, security issues, product defects, legal action, and regulatory compliance.

Several reports claim the counterfeiting of proprietary consumer goods is the world’s most valuable crime racket. In 2022, the sales of counterfeit and pirated products are expected to grow to $2.8 trillion and cost 5.4 million jobs, which is more than drugs and human trafficking. The cannabis industry already has issues with counterfeits and misrepresentation by brands. The issue will only compound as the industry continues to grow around the world. Counterfeiting not only risks the health and safety of consumers, it also disrupts brand revenue and loyalty.

In this blog series, we discuss how cannabis businesses can ensure brand protection with authentication and radio frequency identification (RFID) solutions.

Benefits of RFID in the Cannabis Industry

Adopting RFID technology for inventory management in any industry can save time and money by offering real-time inventory analysis. In the cannabis industry, this is important as the technology simplifies the process for companies to adhere to regulatory tracking needs. Bulk tag reading also allows for reduced headcount.

Additional potential benefits of RFID include:

Automated Data Collection

Cannabis growers have to document nearly everything they do during daily operations.

Depending on the number of plants in a greenhouse, it may take a lot of time for employees to record the data on each plant. Although taking visual stock can be a big help, relying on manual data collection can produce expensive errors.

An RFID system removes human error and allows for reading several tags at the same time, including those that are hidden from sight. It not only decreases human error and cuts down labor overheads, but also allows employees to focus on other tasks.

Inventory and Product Performance Monitoring

Depending on the company location, an inventory discrepancy could result in hefty penalties. For instance, a cannabis dispensary in California could receive fines of up to $30,000 for significant discrepancies (defined as a difference of 3% or more in actual inventory compared to a dispensary’s records).

RFID systems offer automated data collection, so it is easier to stay on top of inventory in real-time and stay compliant with government regulations. Inventory data can also be leveraged to make business decisions and track which products are performing well. This will help to plan ahead and understand customer preferences. This information can also be used to quickly generate inventory reports during compliance inspections.

Security Against Theft

Recently, we have seen a massive spike in robberies at licensed cannabis dispensaries, including pistol-whipping, gunshots, and killings. Industry trackers in Washington have reported at least 80 thefts so far this year. However, theft is not just limited to cannabis shops. In fact, many incidents occur in the multi-billion-dollar supply chain. There are security risks at every stage, from the cultivation facilities, to the manufacturers who are processing the product, to the distributors who are transporting the product, to eventually the retailers.

According to industry experts, the retail link within the cannabis supply chain carries the most risk. This is because most retail shops have a large amount of ready-to-consume cannabis products that can be easily resold on the black market. Plus, banks are reluctant to take deposits from legal cannabis-based companies because of the U.S. federal government’s classification of cannabis as an illegal substance. Consequently, cannabis retailers usually have large amounts of cash held onsite, which obviously makes them a big target.

Temperature Sensing

Cannabis plants require a certain temperature and low humidity to survive and thrive. If the environment becomes too humid, these plants may mold, resulting in the need to repeat the cultivation process.

RFID-based platforms offer environmental sensing capabilities that can help dispensaries monitor their greenhouse’s environment. For instance, RFID can be used to measure the temperature and ambient light in a greenhouse, ensuring the plants are always at the right temperature.

Accuracy and Efficiency

RFID technology provides a drastic increase in accuracy and a corresponding decrease in errors, which improves efficiency and return on investment (ROI) for cannabis businesses.

The potential for errors is much greater with a hand-written record book. Barcodes are easy to miss, easy to double scan, and can be covered by the dirt and grime so prevalent in grow environments. But a properly implemented RFID solution can provide more than 99% accuracy.

RFID also allows fewer workers to get more done. Cannabis operators usually design and pilot their operations in phases. In the initial phases, labor is often not a problem as operations are limited, scales are small, and there are several individuals to monitor and evaluate the growing enterprise. However, cannabis operators can quickly work to transform from a limited pilot operation to full production.

In this case, the only solutions are to either employ multiple new workers or have an automated infrastructure already in place that can manage the sudden surge in size and volume. With a properly designed RFID solution, operators can easily switch from a pilot scenario to full production.

Check back next week as we take a deeper dive into the differences between RFID and barcodes for product tracking in cannabis. In the meantime,

book a meeting with an RFID expert today to learn more about our technology solutions for the cannabis industry.